For 3D printing asssignment of Design and 3D print an object (small, few cm) that could not be made subtractively.

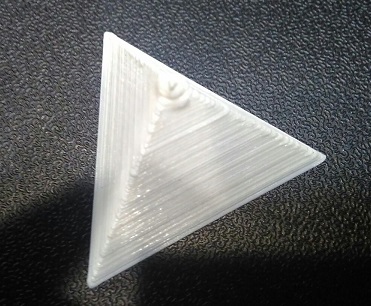

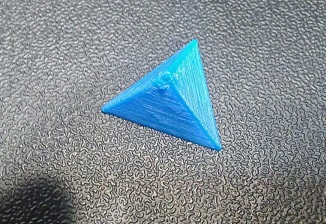

For this thing i thought that i will make a one small pyramid triangle(20*20*20mm).

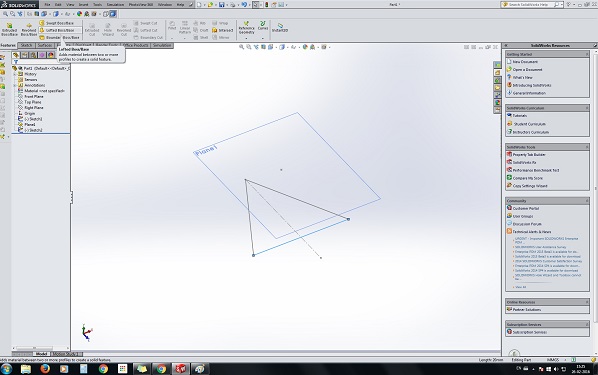

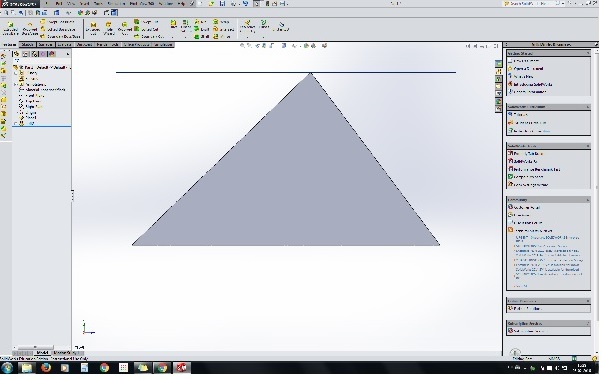

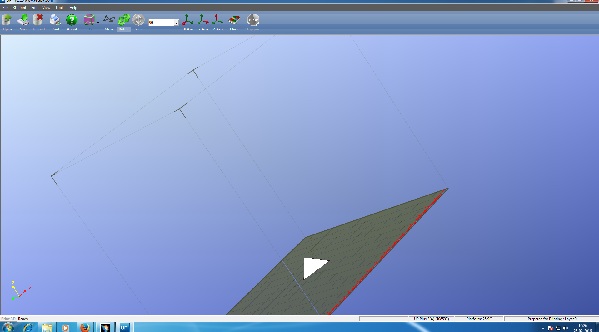

So that i just started to making a pyramid triangle in solidworks .

I went to new part design and choosen the plane1 and made a small triangle of 20*20*20mm and saved into .stl file.

But in our lab we have two 3D printers, 1 Ultimaker2(PLA), 2 Up plus(ABS).

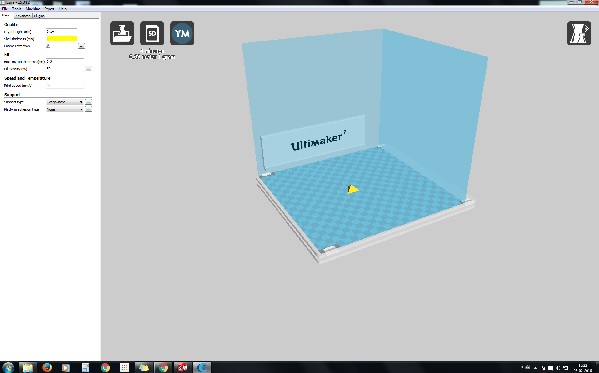

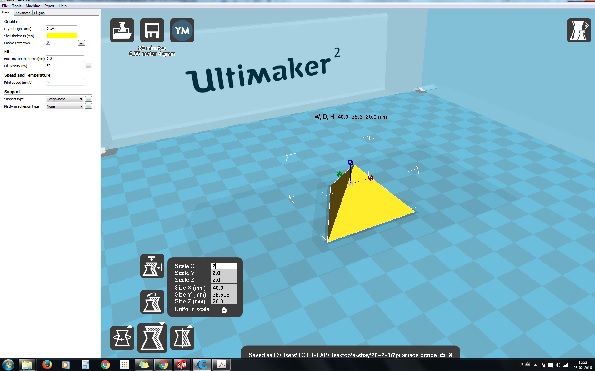

For ultimaker printing we have to make a Gcode in Cura, so just import into cura and set the Layer height 0.1mm,Shell thickness 1mm, Fill Density 80% And print speed 50(mm/s) and saved into Gcode format.

Then insert the card start the ultimaker went to Material change and added the PLA 3mm white filament and selected the PLA material.

Then went to Build-plate Continue it went to some height then manually done the position and set the plate and nozel height with help of a4 paper 0.1mm thickness, and click on continue and made another two(left&right) side and made it another time.

Then went to Print option and selected the Pyramid now its start the tuning after few seconds it started But within some minutes i realise that its not going properly so i just stopped it and went to cura and scale it into 40mm instide of 20mm.

And gives the print another time its starting tuning and nozel is went to 200degree celcius and plate into 40-50degree celcius started the print and now its printing properly.

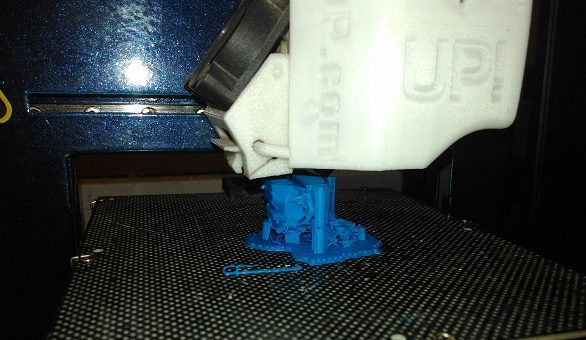

For up plus i just started the software and make Initize the printer then went to maintain Extrude the Material of ABS 500grams added, and connected the 3mm connecter and made bed level and detected the nozzle height and give the print it started.

After completed the those two prints and compair it and i realise that up printer quality and finishing also very nice .

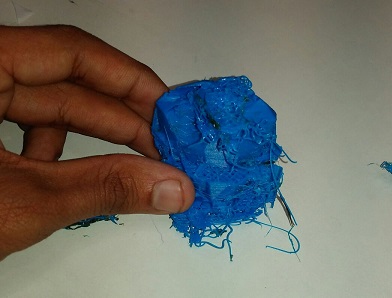

But the both printers are not able to print the upper part just because of its small triangle.

I think Ultimaker stoppes from 3.5mm,Up stoppes from 1.6mm and i try one 10mm cube with the 4mm inner grow and makes 9.95mm cube, 3.65mm grow.

So for me Up plus 3D printer is good.

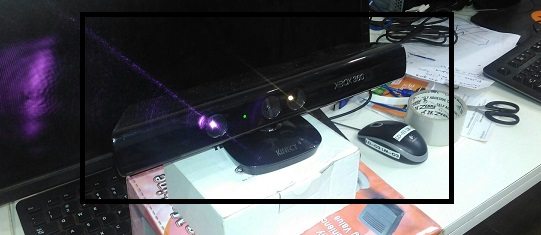

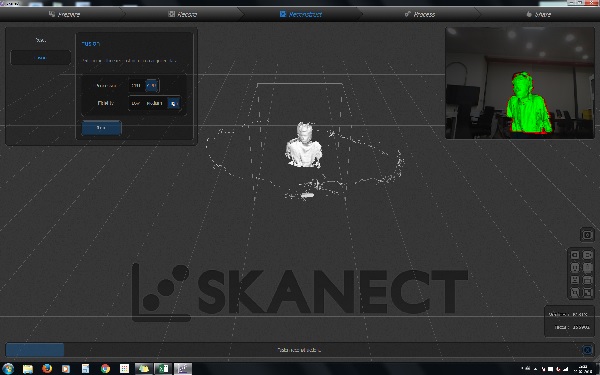

For 3D scanning i choosen the Skanect XBox 360 .

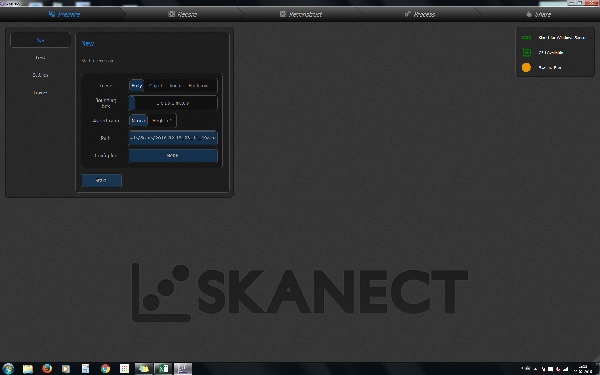

So i installed the Skanect(in windows PC) and just followed the instuction.

So i connected the all connections and start the scanning of my water bottel and then Chair.

Start the Skanect went to new selected Scene is Body and start went to Record set the auto focus.

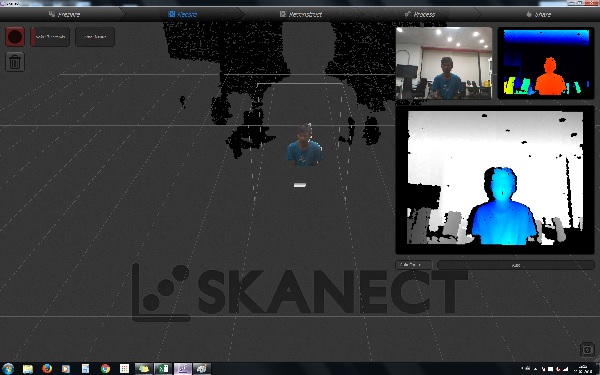

Me and yogesh start the scanning set the Xbox in one place and we are moving in 360Degrees, very slowly.

I started moving in 360 deegrees, But i have to move very slowly or other wise the FPS(Frame Per Second).

After completing it went to share and save into 3D model.

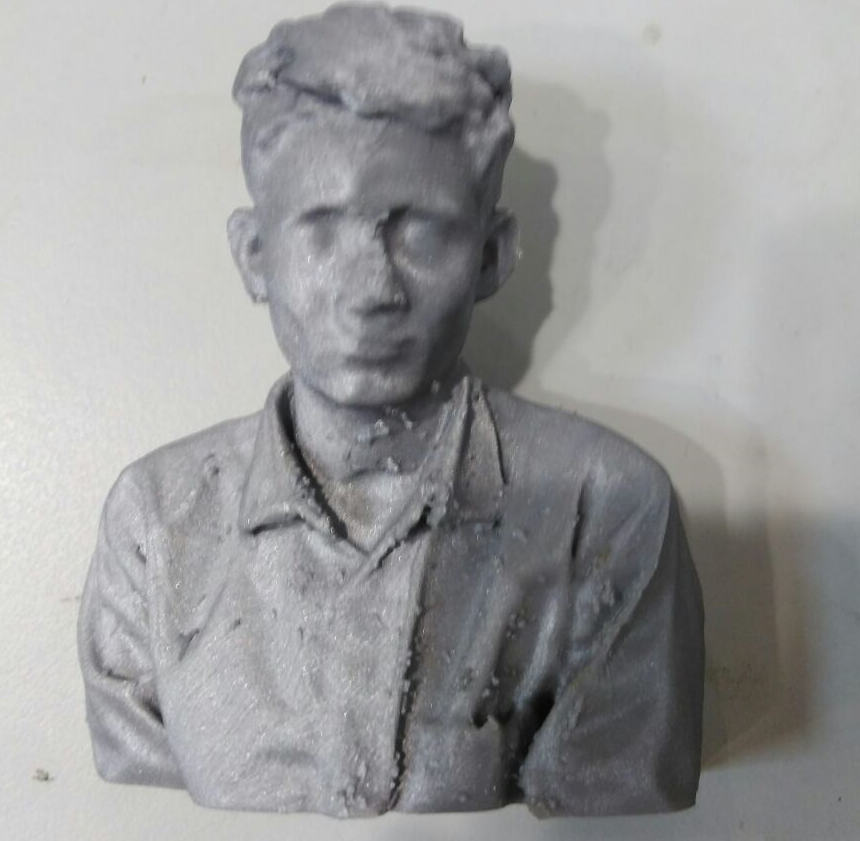

And gives the print to UP printer but it hasn't print it properly, So iam trying it and i will amke it properly very early.

So we scanner another time with Sence scanner

Then we installed the Sence scanner Software.

Then we started scanning of each others in vigyan asharm and its good learning experience.

Following those software steps we done with our .stl file.

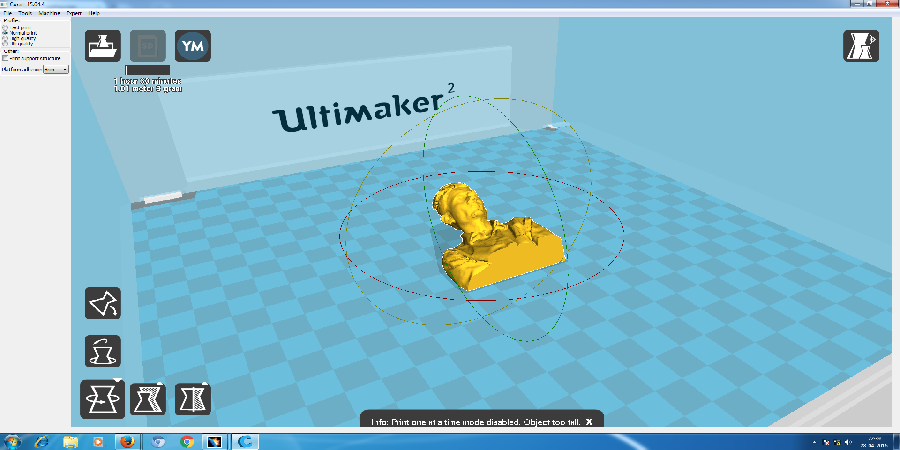

And i opened in Cura but its very large file so scale down it and made the gcode then just print it.

Download the files from here